- Home

- Continuous Stirred Tank Reactor (CSTR)

H2O CSTR PROCESS

H20 CSTR Process For Industrial And Domestic Wastewater Treatment

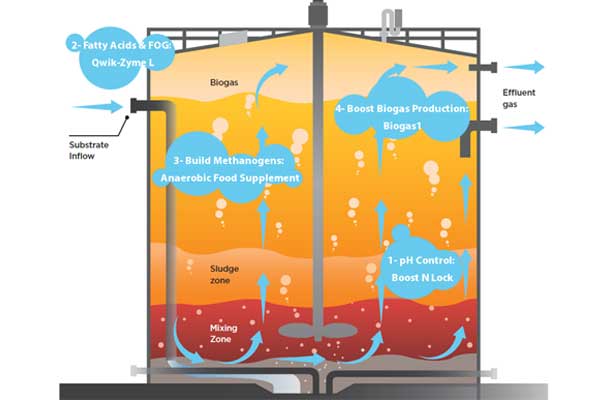

H2O CSTR is completely-mixed form of anaerobic reactor, designed to maximize the contact between the biomass and the waste, to optimize digestion performance. CSTR digester configurations, it is also one of the best in terms of applicability to different wastes. The wastewater (wastewater/sludge mixture) enters the reactor at the bottom and leaves at the top and includes an internal recycle loop which draws reactor contents from the opposite side of the entry. Proper mixing by means of a top-entry, central agitator ensures that the influent is in constant contact with the biomass for optimal mass transfer and conversion of organic content (COD) to biogas.

Advantage Of CSTR Process :

- Low Operating expenses, produces biogas as by product which can be used as energy source.

- Based on proven process, does not requires mechanical aeration and less power consuming.

- Very suitable for high organic wastes.

- The system can handle sludge, slurries or other concentrated wastewaters;

- Suitable for high fats, oil and grease (FOG) concentrations;

- Can manage very high suspended solids (TSS) concentrations.

- Suitable for high protein (nitrogen) content wastes.

- Simple design short construction period

- Optimal heat- and material distribution inside the digester

- Large digester volumes possible

Applications :

- Petrochemical and field operations.

- Dairy processing (milk, cheese, yogurt)

- Beverage factories (breweries, juice, soda)

- Municipal sewage plants

- Pulp & paper

- Aquaculture & hatcheries

- Food processing, Tanneries animal products wastewater

Specifications & Special Features :

- Available in any capacity, in prefabricate & in civil tank type configuration.

- Optimum design for CSTR process with low power requirement and lower op-ex.

- Available in many configuration and options in type, Material of construction,

- Adequately designed pre and post treatment

- Easily expandable and suitable for augmentation projects of old treatment plants to enhance capacity and quality of treated water.

- Suitable technology for phase wise operation & start-up of system.

H2O CSTR Standard Model Configuration

| Model Code | Capacity | Type | Features |

|---|---|---|---|

| A. H2O – CSTR | |||

| HPCSTR-5000 | Suitable upto 5000 Kg/ COD | Fabricated structure in MS / CS / GFSS tanks. Anticorrosive painting or lining option available. | Suitable option for export applications. Rapid construction time. |

| HPCSTR- CL | Any capacity above 100 Kg/Day COD | Tanks in Civil construction | Long life durable option. |

Continuous Stirred Tank Reactor, H2O CSTR Process, H20 CSTR Process For Industrial And Domestic Wastewater Treatment In Mumbai, India